Introduction

In hazardous environments where explosive gases, vapours, or combustible dusts are present, ensuring electrical safety is of paramount importance. Cable glands play a crucial role in providing a secure and safe electrical connection between equipment and cables in these hazardous areas. However, in many cases, cable glands are installed incorrectly, leading to significant safety hazards.

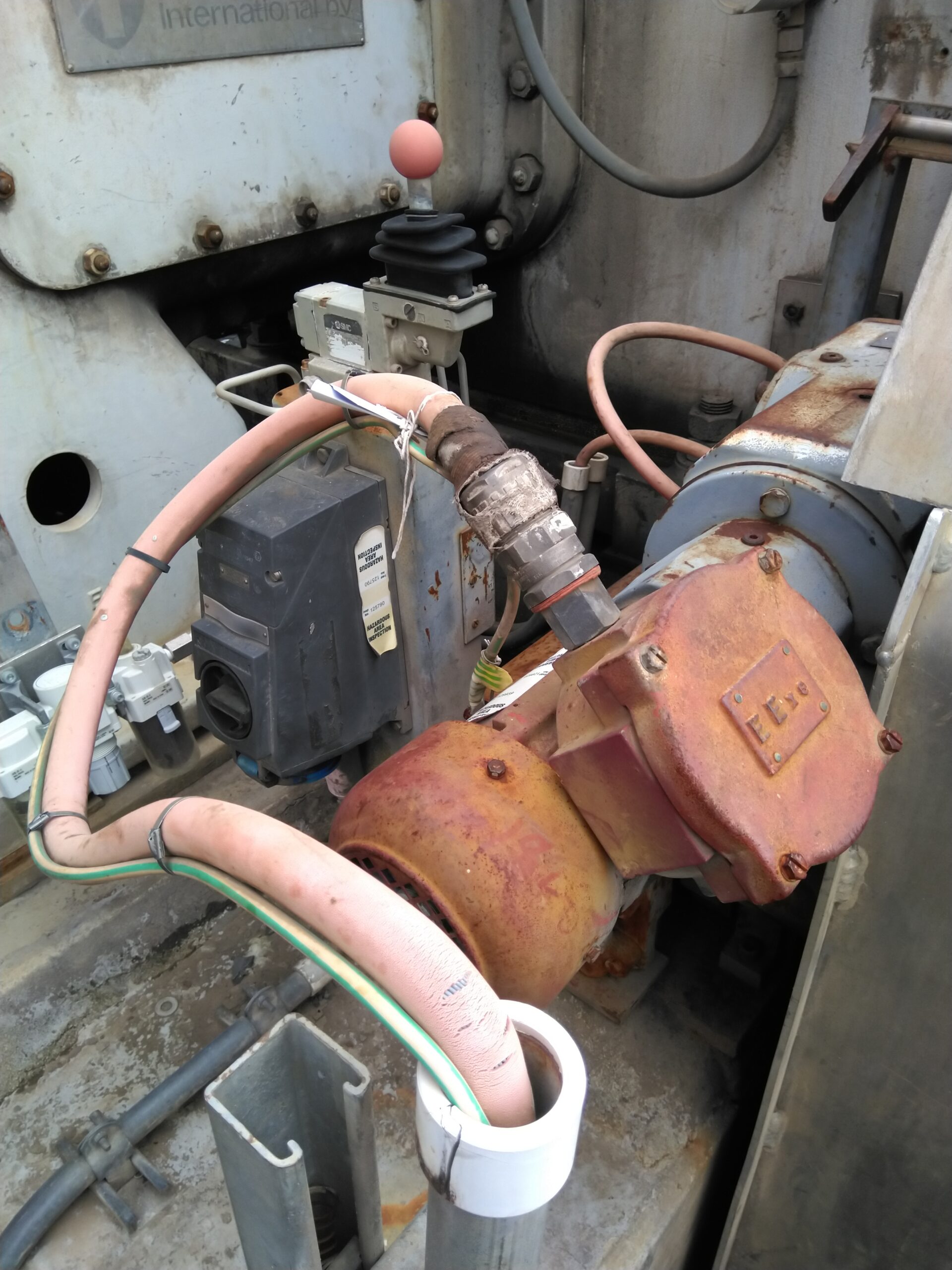

One common issue is the exposure of Steel Wire Armored (SWA) cables out the back of the gland. This article explores the potential problems that can arise when cable armour is exposed and emphasises the importance of adhering to IEC60079 standards for safe cable gland installations.

The Importance of Proper Cable Gland Installation

Correctly installing cable glands is critical for maintaining the integrity of hazardous area enclosures. Glands are used to secure and seal cable entry points to prevent the ingress of explosive gases or dusts. An improper installation can compromise the level of protection offered, leading to potentially disastrous consequences.

Exposure of Cable Armour (SWA) and the implications

One common mistake in cable gland installation is the improper handling of Steel Wire Armored (SWA) cables. SWA cables are widely used in hazardous areas for their robust construction and resistance to mechanical damage. However, when SWA cables are exposed out the back of the gland, several problems may arise:

1. Reduced IP Rating: The IP (Ingress Protection) rating indicates the level of protection against solid particles and liquids. When SWA cables are exposed, the IP rating of the cable gland is significantly reduced, allowing hazardous substances to penetrate the enclosure and potentially come into contact with live conductors.

2. Increased Risk of Mechanical Damage: In hazardous areas, the risk of physical impact is high due to various industrial activities. Exposing the SWA cables leaves them vulnerable to damage, such as crushing, cutting, or abrasion, which can lead to short circuits or expose live conductors.

3. Compromised Earth Continuity: Properly terminated and clamped SWA cables provide an effective earth continuity path, essential for fault protection and safe electrical operation. Exposing the cable armour can disrupt the earth connection, leading to potential hazards during fault conditions.

4. Risk of Corrosion: Hazardous environments often contain corrosive substances, which can attack the exposed SWA cables, compromising their mechanical integrity and electrical conductivity over time.

5. Non-compliance with IEC60079 Standards: Exposing SWA cables directly contradicts the IEC60079 standards, potentially leading to legal and regulatory implications for the installation.

Adhering to IEC60079 Standards

To ensure the safety of installations in hazardous areas, it is vital to strictly adhere to the guidelines outlined in the IEC60079 series. When installing cable glands, the following best practices should be followed:

1. Choose Appropriate Cable Glands: Select the correct cable glands which have been specifically designed for hazardous environments and suitable for the cable type being used. The glands must be certified to meet the relevant IEC60079 standards.

2. Verify IP Ratings: Ensure that the cable gland, when correctly installed, maintains the desired minimum IP rating to protect against the ingress of hazardous substances.

3. Utilise Proper Glanding Techniques: Follow manufacturer guidelines for installing cable glands, paying particular attention to SWA termination methods to maintain the integrity of the cable armour.

4. Provide adequate cable support: Often, the stress applied to the back of the cable gland is increased by the lack of cable support. Over an extended period of time the cable, UV exposure and other mitigating factors could cause the cable armour to become exposed.

5. Perform Regular Inspections: Periodically inspect and maintain cable glands to identify any signs of damage, wear, or corrosion, ensuring prompt replacements when needed.

Conclusion

In hazardous areas, cable glands are essential components for safeguarding electrical installations against potential ignition sources. However, incorrect installation practices, such as exposing SWA cables out the back of the gland, can compromise safety, leading to serious consequences.

To mitigate risks and ensure compliance with safety standards, it is imperative to adhere to the guidelines outlined in the IEC60079 series. By doing so, industries can create a safer working environment and reduce the likelihood of accidents, protecting both personnel and assets from harm.

Follow us on LinkedIn