Empowering Field Technicians with Smart Inspection & Workflow Management

Technicians working in the field face the challenge of conducting inspections efficiently while maintaining rigorous standards. Enter FieldView, a cutting-edge software solution that has not only transformed the inspection process but has also evolved into a comprehensive workflow management tool.

In today’s dynamic industrial landscape, managing a successful power station demands precision, real-time data access, and seamless synchronisation between field technicians and their operational hubs. FieldView, leverages the power of 4G and WiFi technology to provide instant access to all the information required for efficient equipment inspection and workflow management.

The FieldView Evolution: From Hazardous Areas to Beyond

FieldView was conceived out of a genuine desire to enhance hazardous area inspection software. As the software evolved, it became apparent that FieldView had the potential to offer so much more. FieldView has expanded its scope significantly. Today, it serves as a versatile tool that assists team members in managing workflow from creation to compliance.

Its applicability extends to various industries and inspection types, making it a valuable asset for organisations seeking operational excellence.

We use the iSafe brand of Ex (IECEx certified) tablet (i930.1).

Streamlined Inspection & Reporting Processes

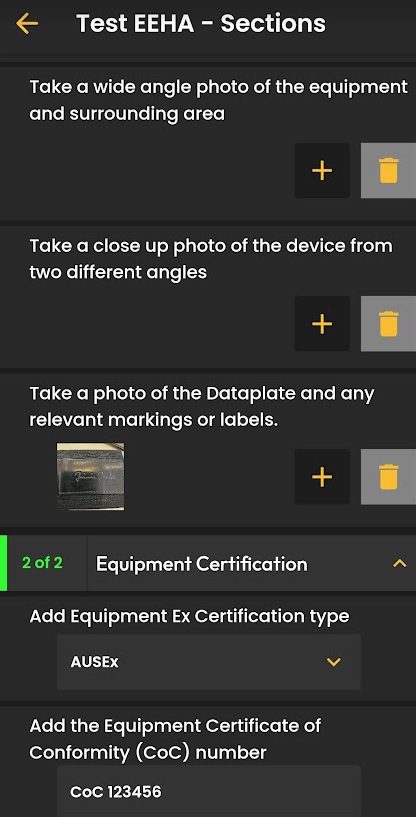

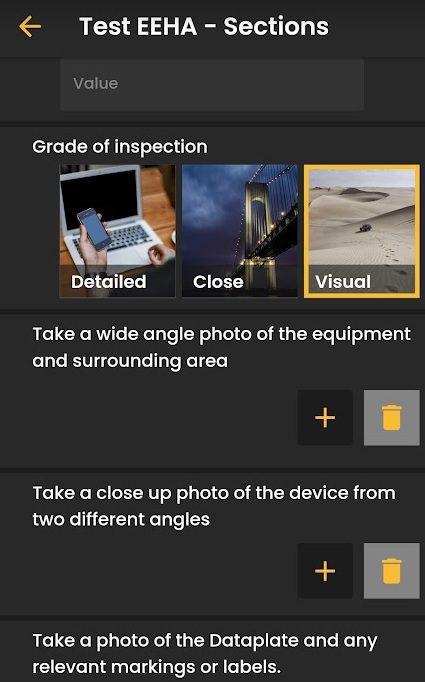

FieldView simplifies the inspection process by harnessing the power of tablet technology. Technicians equipped with tablets can seamlessly access preformulated inspection forms, eliminating the need for paper-based documentation.

This not only saves time but also reduces the risk of errors associated with manual data entry.

Real-Time Data Capture

One of the standout features of FieldView is its ability to capture inspection data in real time. Technicians in the field can input data directly into the tablet based system, ensuring that supervisors and team members have access to up-to-the-minute information.

This real-time visibility enhances decision-making and allows for immediate corrective actions when necessary.

Seamless Offline Functionality: Keeping Operations Uninterrupted

FieldView recognises that field technicians often work in areas with limited or no connectivity. To address this challenge, the software offers seamless offline functionality. Technicians can confidently carry out their tasks even when disconnected, with the assurance that there will be no synchronisation problems when they regain connectivity.

This capability eliminates disruptions and allows for uninterrupted workflow management.

Collaborative Workflow Management for optimal productivity

FieldView is not just a tool for technicians; it’s a collaborative platform that empowers teams to manage workflow efficiently.

Supervisors, planners, schedulers, and team members alike can monitor the data captured in real time. This feature is invaluable for planning, scheduling, and prioritising work assignments, resulting in optimised productivity.

Work Instruction and Work Packs

The software goes beyond data capture by offering the ability to create work instructions and work packs based on the data collected during inspections. This seamless integration streamlines the process of translating inspection findings into actionable tasks. It ensures that the right steps are taken to address issues promptly and efficiently.

RFID Technology for Equipment Identification

Efficiency is at the heart of FieldView’s design. Each piece of equipment is equipped with an RFID tag, allowing technicians to quickly and accurately identify it. Using intrinsically safe tablets, technicians can easily scan equipment tags, saving valuable time and reducing the risk of errors associated with manual identification.

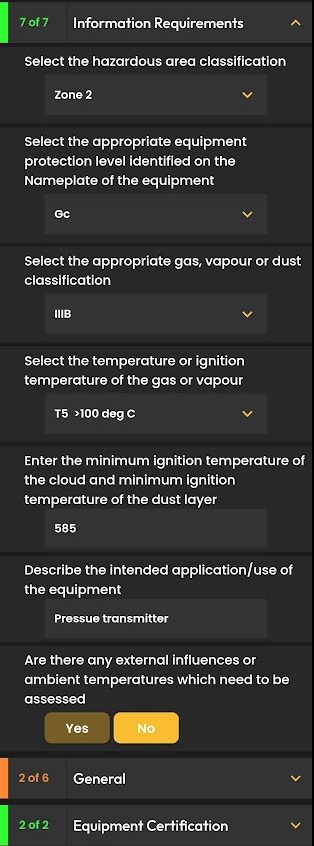

The Power of Customisable Business Rules

One of the major advantages of FieldView is its flexibility in accommodating business rules and requirements. For instance, if instrument calibration demands a particular level of accuracy, FieldView makes it easy to program those requirements directly into the calibration form. This level of customisation ensures that your power station’s unique standards are consistently met.

Translating Inspection findings into action

FieldView assists in translating inspection findings into actionable tasks, improving the efficiency of issue resolution. The system caters to a wide range of tasks that are crucial for power station management. Technicians can select from various tasks, including:

- Hazardous Area Inspection

- Instrument Calibration

- High Voltage Testing Reports

- Failure Analysis Reporting

- Electrical Installation Testing

- Work Scope Development

- Incident Reporting

This versatility ensures that FieldView is adaptable to the specific needs of your power station, offering a comprehensive solution for various inspection and maintenance requirements.

Embrace the Future of Power Station Management

We encourage our clients to embrace FieldView as a game-changing solution that empowers field technicians and operational teams to work more efficiently and safely, ultimately driving operational excellence in the power industry. Our system works!!!

Conclusion

In conclusion, FieldView is a game-changing solution that not only enhances equipment inspection and workflow management but also adapts to the unique needs of your power station. With its advanced technology, offline capabilities, RFID integration, task versatility, customisable business rules, and real-time form creation, FieldView empowers field technicians and operational teams to work more efficiently and safely.

It’s more than software; it’s a catalyst for operational excellence in the power industry. Embrace FieldView and experience the future of power station management today.

Your blog post was like a guidebook that provided clear directions and valuable insights. I appreciated the practical advice you offered.