Gas Tightness Testing pipework in Industrial Gas (Type B) appliances

In Australia gas is a fundamental source of energy in large parts of our energy industry. Gas tightness testing (Gas Leak Detection) on industrial Type-B gas appliances is a crucial step in ensuring that gas pipework and appliances are installed and maintained in a way that prioritises safety.

In this article, we will explore the significance of gas tightness testing before and upon the completion of gas pipework and appliances.

Ensuring Safety

The primary and most critical reason for conducting gas tightness testing is to ensure the safety of personnel working on and near industrial gas appliances.

Leaks in gas pipework or Type-B industrial gas appliances can lead to catastrophic consequences, including fires and explosions. Gas tightness testing involves pressurising the system and checking for any loss of pressure, thereby identifying even the smallest leaks that may pose a risk.

Compliance with Regulations

Gas tightness testing is not just a good practice; it’s a legal requirement. Compliance with the gas regulations is essential to avoid legal penalties, but more importantly, it ensures that gas systems are designed and operated in a way that minimises risks to public safety.

Refer to AS/NZS5601.1:2022 Appendix E – Testing for gas tightness for further details regarding the gas tightness standards.

For gas installations where the volume of pipework does not exceed 30 Litres the test period shall be 5 min. Where pipework volume exceeds 30 Litres, the test period shall be extended by 5 minutes for every 30 Litres or part thereof.

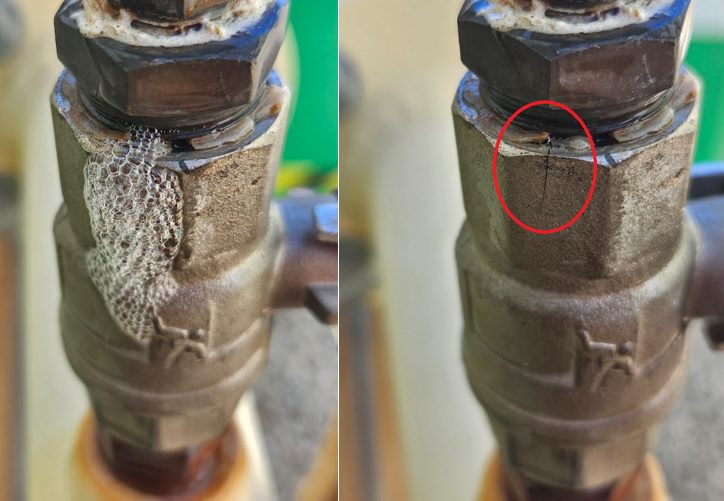

During a recent gas service job on a generator set, a pre-work pressure test aided in the detection of a minor crack in an isolation valve. A gas tightness test pinpointed the presence of the cracked valve, and through additional inspection, we successfully identified the location of the crack using a leak detection fluid.

Gas Tightness Testing | a small crack was identified in the valve body

A non-corrosive soap and water solution or leakage detection fluid externally or other suitable gas detecting equipment or means shall be the only methods used to locate a gas leak.

CAUTION – The ammonia present in some soaps and detergents can react with brass fittings and cause such fittings to crack after a short period of time. Therefore, caution should be exercised when using soap solutions on brass fittings and all connections should be rinsed thoroughly with fresh water as soon as possible after the application of the soap.

Pipework Test Procedure for ‘new installations’

According to (AS/NZS 5601.1:2022 Appendix E.4).

The pipework test shall be carried out as follows:

- Ensure all open ends or plugs are sealed.

- Ensure all interlocks are in the open position.

- Connect a suitable test instrument.

- Isolate the pressure source.

- Pressurise the consumer piping to either 1.1 or 1.5 times the operating pressure, depending on the installation nominal pressure. Or to the pressure setting of any over pressure devices, whichever is less.

- Allow a period of at least 2 minutes for the temperature of the testing medium with the consumer piping to stabilise.

- For pipework volumes up to 30 Litres, measure the loss of pressure during the test period of 5 minutes. For pipework volume exceeding 30 Litres, the test period shall be extended by 5 minutes for every 30 Litres or part thereof.

Pipework shall be deemed to be gastight and the test satisfactory if there is no loss of pressure during the test period.

NOTE: The test period does not include the temperature stabilisation period.

Testing a connection made after pressure leak testing

AS/NZS 5601.1:2022 Appendix E.7 – Testing a connection made after a test procedure

Any connection made after a test has been completed shall be checked for leakage at operating pressure. A suitable leak detection solutions or other suitable leakage detection method shall e used and the connection left gastight.

A good method for testing valve seating integrity (in conjunction with pressure testing) on industrial Type-B gas appliances, is the bubble method (as seen in the below video). The footage was taken during routine maintenance on a Solar Turbines gas turbine engine service.

The secondary block valve was suspected to be passing, and this method was used to prove our suspicions.

Conclusion

Gas tightness testing is a crucial step in ensuring the safe operation of industrial Type-B gas appliances. Compliance with regulations and industry standards is essential. Periodic testing should be part of routine maintenance schedule to maintain the integrity of gas systems.

GENEX ENERGY provide full turnkey solutions for the safe design, installation, commissioning and servicing of industrial Type-B gas appliances. Read more about our industrial gas system services.

Follow the story on LinkedIn.