Introduction

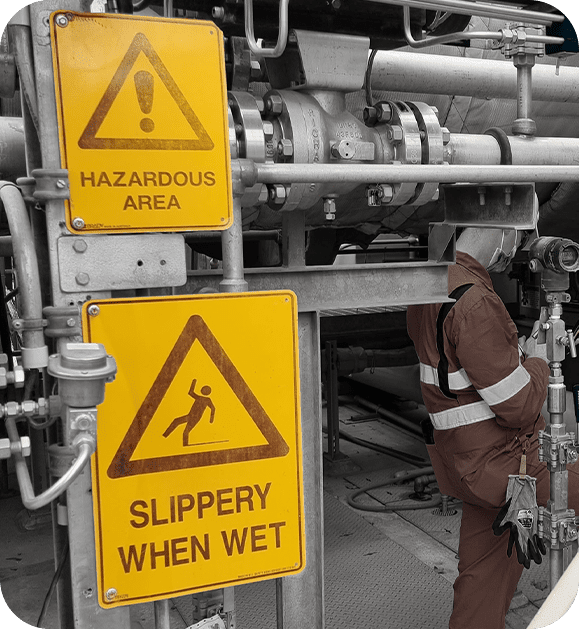

In industries where explosive atmospheres are present, ensuring the safety of personnel and equipment is paramount. The IECEx AS/NZS 60079 standards provide comprehensive guidelines for the management of hazardous areas. As part of this framework, a Hazardous Area Verification Dossier (HAVD) plays a crucial role in documenting the assessment and verification process. In this article, we will explore the requirements for a HAVD, outlining the key components that must be included.

AS/NZS 60079.14 defines a verification dossier as:

a set of documents showing the compliance of electrical equipment and installations.

The standard also outlines the necessity to:

ensure that any installation complies with the relevant equipment certificate as well as with this standard and any other requirements specific to the plant on which the installation takes place. To achieve this result, a verification dossier shall be prepared for every installation and shall be either kept on the premises or stored in another location. In the latter case, a document shall be left on the premises indicating who the owner or owners are and where that information is kept, so that when required, copies may be obtained.

What should be included in a HAVD?

AS/NZS 60079 specifies that a verification dossier that contains evidence of compliance of equipment with Australian Standards or other approved standards, must be developed and kept updated for the service life of the installation.

AS/NZS 60079.17 details the information required to be kept in the dossier. Examples of the type of information required to be kept is shown below. Note that this is not the full list but is provided to give an indication of what is required within the dossier and reference should be made to AS/NZS 60079 for full details.

Requirements for other documentation that may be necessary are provided in IEC 60079-14 and IEC 60079-17. It is the responsibility of the legal owner/s of the installation to provide the dossier and to ensure that it is kept up to date.

1. Scope & Purpose

The HAVD serves as a comprehensive record that verifies compliance with the relevant standards and regulations. It provides a clear overview of the hazardous area classification, equipment selection, installation details, and ongoing maintenance requirements. The purpose of the HAVD is to demonstrate that all necessary precautions have been taken to minimize the risk of ignition sources and ensure a safe operating environment.

2. General Information

The HAVD should begin with general information, including the project name, location, and identification of the hazardous area. This section also outlines the scope and objectives of the verification process, including any specific standards or regulations followed.

3. Hazardous Area Classification

A detailed hazardous area classification report must be included in the HAVD. This report identifies and categorizes areas where explosive atmospheres may occur based on the type and frequency of hazardous substances present. It should include drawings, plans, or schematics that clearly indicate the extent of the hazardous zones. Zone classification of areas and, if included, the equipment protection level (EPL) required for each location

4. Equipment Selection & Installation Details

This section provides a comprehensive overview of the selected electrical and non-electrical equipment installed within the hazardous area. It includes a list of all equipment, their associated hazardous area zone classifications, and relevant certification details. Documentation such as equipment datasheets, test reports, and certificates of conformity should be included.

- For gases: equipment group (IIA, IIB or IIC) and temperature class requirements

- For dust: equipment group (IIIA, IIIB or IIIC) and maximum surface temperature requirements

- Equipment characteristics e.g., temperature ratings, type of protection, IP rating, corrosion resistance.

5. Inspection & Testing Records

The HAVD should contain records of inspections and tests conducted during the verification process. This includes initial visual inspections, continuity and insulation resistance tests, and detailed examinations of equipment installation. The records should highlight any non-conformities identified and the corrective actions taken to rectify them. Copies of previous inspection records. Copy of the additional initial inspection records as detailed in IEC 60079-14.

6. Ex Equipment Maintenance

To ensure ongoing safety and compliance, the HAVD must outline the maintenance requirements for the installed equipment. This includes documentation of planned maintenance schedules, procedures, and records of all maintenance activities conducted. It is essential to include details of any modifications or repairs made to the equipment, along with relevant certification or approval documentation. Records sufficient to enable the explosion-protected equipment to be maintained in accordance with its type of protection (see IEC 60079-14), (for example list and location of equipment, spares, certificates, technical information).

7. Verification Reports

The HAVD should include all verification reports and certificates issued during the verification process. These reports are generated by competent personnel who have conducted the necessary inspections, tests, and assessments. They provide an independent assessment of the compliance of the hazardous area installation with the applicable standards.

8.Evidence of equipment compliance

Electrical Inspectors inspecting electrical installing work involving hazardous areas will ask to see the dossier. The evidence is to comprise a Certificate of Conformity (CoC) issued in accordance with the Australian National Certification Scheme the “ANZEx Scheme” – or by carrying IECEx certification issued in accordance with the IECEx Scheme.

9. Competency and Training Records

To demonstrate the competence of personnel involved in the verification process, the HAVD should include documentation of their qualifications, certifications, and training records. This ensures that the verification activities are carried out by individuals with the necessary expertise and knowledge. The Standard also requires that persons who install, maintain, repair, overhaul or inspect such installations must be competent to do so. To be competent, the person must have had appropriate training in the class of work to be undertaken. National Electrical Equipment in Hazardous Area Competency Standard AS/NZS 4761 details the competencies required.

10. Hazardous Area Managment System

If your organisation operates a major hazard facility, it is strongly advised that a hazardous area management plan is compiled as part of the safe system of work in hazardous areas.

Conclusion

A Hazardous Area Verification Dossier (HAVD) is a comprehensive document that ensures compliance with the IECEx AS/NZS 60079 standards. By including all the required components outlined above, the HAVD serves as a valuable resource for demonstrating the proper assessment, selection, installation, and ongoing maintenance of equipment within hazardous areas. Adhering to these requirements and maintaining an up-to-date HAVD is crucial for maintaining a safe operating environment and minimizing the risks associated with explosive atmospheres.

Ask us a question on LinkedIn.