The Importance of Safe Gas Purging

Gas purging is a crucial process in many industrial applications, ensuring the safe removal of hazardous gases from pipelines before work commences. To uphold safety, the Australian Standards AS5601 and AS3814 provide comprehensive guidelines for gas purging techniques and practices.

In this article, we will explore the importance of safe gas purging, the key principles outlined, and best practices for achieving a secure gas purging process.

The purpose of purging is to prevent the presence in the piping of an explosive mixture of gas and air.

Purge or Purging (with respect to consumer piping) is defined as:

- Replacing the air in consumer piping with gas or inert gas; or

- Removing the gas from consumer piping by replacing the gas with either air or an inert gas.

Why is gas purging important?

Purging is carried out to avoid the possibility of an explosive air/gas mixture existing or forming in piping, appliances or confined spaces. Purging is required when commissioning or decommissioning a gas system, part of a gas system or a gas appliance.

Purging is the displacement of:

- Air, or an inert gas, by a fuel gas.

- A fuel gas by an inert gas.

Nitrogen is the preferred inert gas.

- Smaller volume gas systems can be purged in line with the methods provided in AS/NZS5601.

- Where large volume gas systems (>30 litres = 0.03 m³) are to be purged a specific ‘purge procedure’ will be required.

Gas purging is essential for a variety of reasons

Safety | Purging removes flammable, toxic, or reactive gases from pipelines, reducing the risk of fires, explosions, and health hazards to personnel. Proper purging ensures that the environment within the system is suitable for the subsequent process, such as welding, maintenance, or repairs.

Environmental Protection | It prevents the release of potentially harmful gases into the atmosphere, contributing to environmental conservation.

Standards

The Gas Installation Standards (AS5601.1), sets the guidelines for gas installation and usage in Australia.

The Standard AS3814 (Industrial and Commercial Gas-fired Appliances) provides guidelines for the installation and maintenance of gas-fired appliances. While it focuses on appliances, it also outlines safety measures related to gas purging.

Best Practices | Safe Gas Purging

In addition to adhering to AS5601 and AS3814 standards, here are some best practices to follow during gas purging:

Risk Assessment | Conduct a comprehensive risk assessment before starting the purging process to identify potential hazards and plan accordingly.

Documentation | Maintain detailed records of the purging process, including gas concentrations, flow rates, and safety checks. Purging tasks should have Safe Work Method Statements or Safe Work Instructions for carrying out the purge.

Safe Shutdown | Appliances must be shut down safely before purging.

Isolation | Isolate the gas supply to the section being purged. Ensure proper venting to prevent gas buildup during isolation. Prevent inadvertent operation of any electronic device.

Purge Medium | Use an appropriate purge medium, typically an inert gas like nitrogen, to displace hazardous gases effectively. Do not use air to purge a gas system.

Flammability Levels | There are set limits depending on the gas being purged. Purging shall continue until tests indicate the gas installation is completely free of gas at all purge points. For natural gas, the limits are <2% natural gas content and the upper limit is >95% natural gas. Ensure the gas is vented from the pipe system to safe place and level.

Controlled Flow | Maintain a controlled flow rate of the purge gas to prevent turbulence and ensure a gradual displacement of the hazardous gas.

Ignition Sources | The standard requires that the purged gas be purged a minimum of 6m away from the nearest source of ignition if the volume of gas to be purged is >30 Litres.

Monitoring | Continuously monitor gas concentrations using appropriate gas detection equipment.

Ventilation | Ensure proper ventilation during the purging process to disperse any residual gases safely.

Personnel Training | All personnel involved in gas purging should be adequately trained in safety procedures and equipment operation.

Emergency Response | Have a well-defined emergency response plan in case of unexpected incidents during purging.

Working on a gas installation

Any gas installation, or part affected, that contains gas shall be isolated and, if necessary, safely purged before any gasfitting work commences on that gas installation. Specialised equipment, skills and safe practices shall be used.

All air and contaminants shall be purged from the consumer piping after work on the consumer piping has been completed, and before any attempt to commission the gas installation or operate ant connected appliance.

All existing pipework shall be isolated from its gas supply and safely purged of gas before the work is started.

A typical valve train fitting line.

Purging a large volume gas installation

A large volume gas installation is this context is one with a total installed pipe volume exceeding 0.03 m3.

Purge a large volume gas installation to outside atmosphere. Keep purge outlet at least 6m away from any ignition source and well clear of any opening into a building.

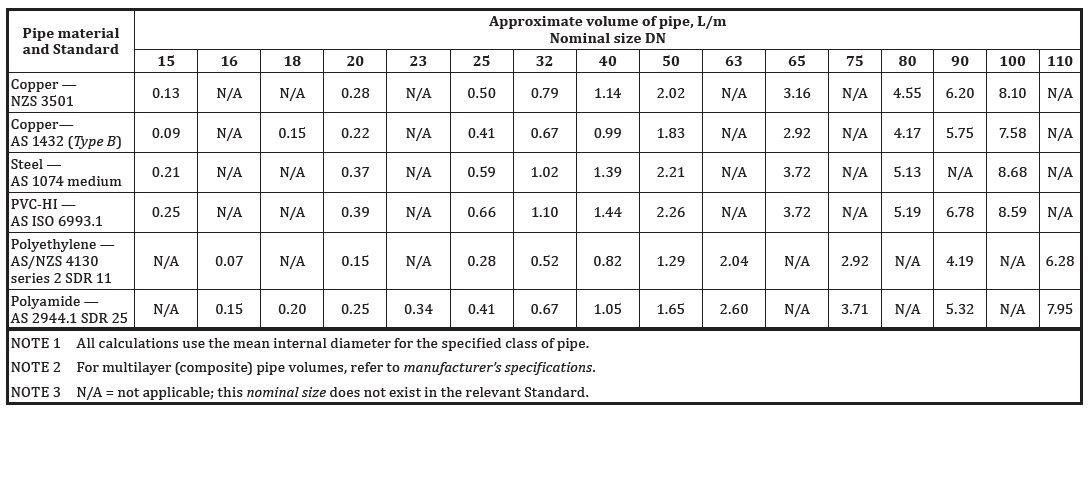

ASNZS 5601.1 (Table D.4.1) Approximate volume of pipe

Purging consumer piping to remove gas

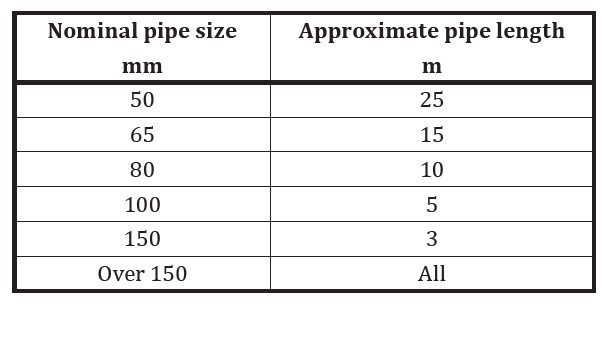

If the section involved exceeds the length shown in Table D.6 (ASNZS 5601.1), displace the remaining fuel gas using an inert gas.

During the purge, continuously check the air/gas ratios using a calibrated gas detector, set for the appropriate gas, to indicate when the purge is complete.

For natural gas, the air/gas ratio is <2%. This ensures the air/gas ratio is below the Lower Flammability Level (LFL) of 5%.

For large installations and where the pipe size exceeds 100mm, inert gas may need to be used as a buffer between air and gas. Purging procedures for such systems should be prepared on a case by case basis by the commissioning engineer or other competent person.

Where consumer piping is to be opened for alteration, repair or extension, isolate the section involved from the gas supply at a convenient point, vent the piping to the outside atmosphere and purge immediately.

Pipe length above which an inert gas purge is required

Commencing the purge

- Plan a method of purging that will ensure that no pockets of air will be left within any part of the consumer piping.

- Ensure that all appliance connections are gastight, all appliance gas valves are turned off and there are no open ends.

- Where adequate ventilation cannot be ensured use flexible piping to direct the purged gas to outside atmosphere.

- Ensure the area is well ventilated, unconfined and free of possible ignition sources, mechanical air inlets or other potential hazards.

- Branches that do not have an appliance connected also require purging. Ensure such branches are fitted with a plug or cap.

Purging after completion of work

After performing any work on consumer piping, all air or inert gas shall be purged from the consumer piping before any attempt is made to light an appliance. All branch lines shall be individually purged. Purging shall be completed before appliance testing and commissioning commences.

Key take-aways

- The gas system MUST be purged in accordance with a safe ‘purge procedure’.

- Large volume (>30L volume) of consumer piping MUST be purged to the outside atmosphere, and at least 6m from any ignition source.

- The air/gas mixture MUST be be proven to be below LFL when purging and above UFL when charge purging. For natural gas, this is <2% and >95%.

Recommendations

- Gas Work License/Authorisation holders should ensure they are familiar with the principals of purging.

- Gas Work Licence and Authorisation holders must only conduct gas work in accordance with their licence or authorisation.

- Large volumes of gas should be purged to well-ventilated outdoor areas which are free of sources of ignition.

- Gas work License/Authorisation holders should undertake refresher training if they are not confident in purging methods.

Conclusion

In conclusion, gas purging is a critical procedure to ensure safety, quality, and environmental protection in industrial settings. Following AS5601 and AS3814 standards, along with best practices, is essential to achieve a safe and efficient gas purging process. By adhering to these guidelines and maintaining a strong commitment to safety, industries can mitigate risks and ensure the well-being of personnel and the environment.

References

- AS/NZS 5601.1 – 2022 Gas installations Part 1: General Installations.

- AS3814 – Industrial and Commercial Gas-Fired Appliances.

Hello I am so happy I found your website, I really found you by mistake,

while I was researching on Yahoo for something else, Anyways I am here now and would just like to say kudos for a

remarkable post and a all round interesting blog (I also love the theme/design).